Creating an Efficient Warehouse Layout

Creating an Efficient Warehouse Layout

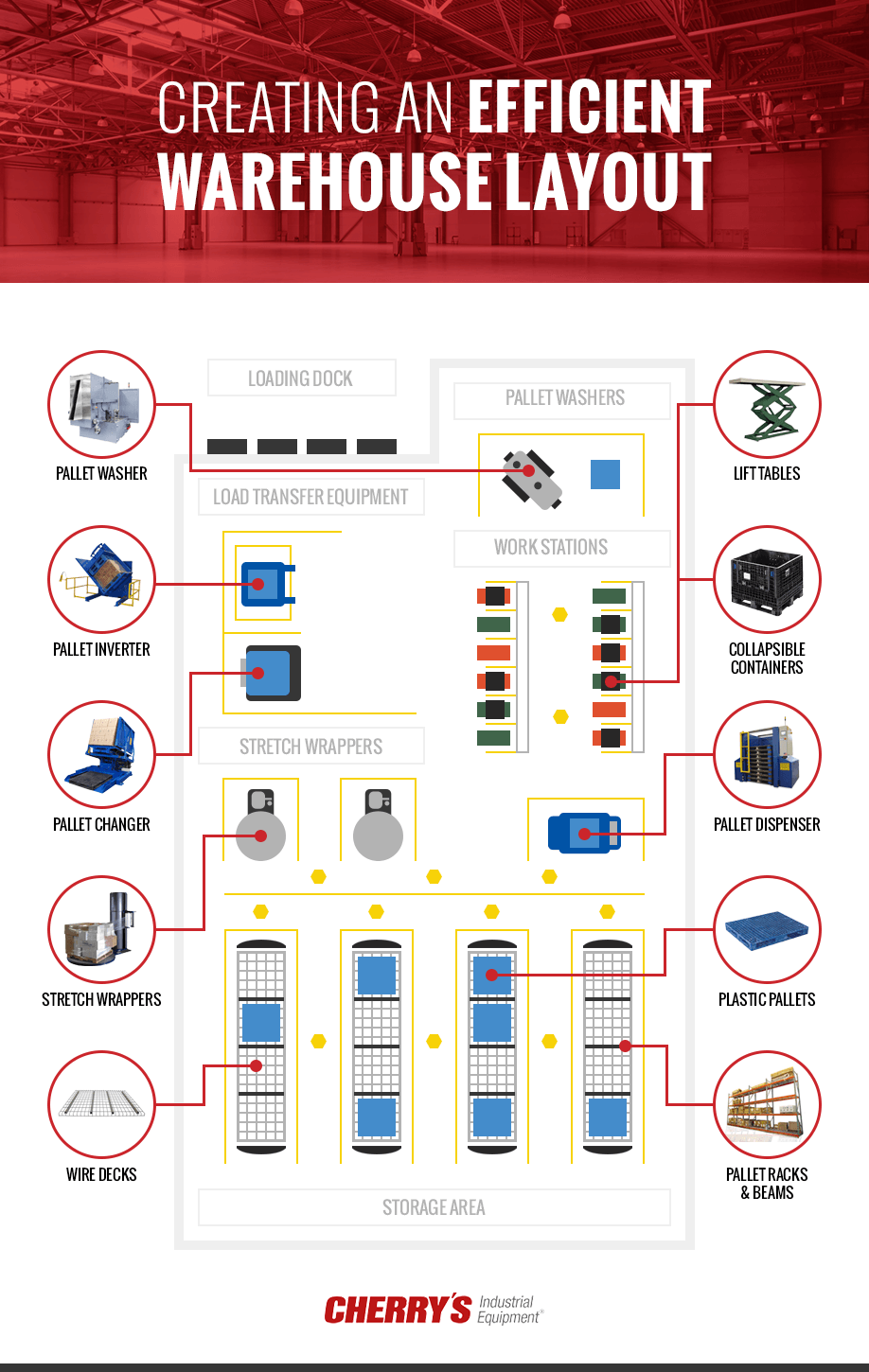

The efficiency of a warehouse depends heavily on its layout. Heavy equipment needs to be able to move freely, and each item should have an assigned spot to ensure it is easy to find. How can you create the most efficient warehouse layout possible?

Load Transfer Equipment

An optimal warehouse layout relies on load transfer equipment that is strategically placed throughout the facility. Employees shouldn't be expected to move or manipulate these large palletized loads by hand. Some items that fall within this category include:

- Pallet Changers:These are ground loaded units that transfer loads from one pallet to another without squeezing or pressing against the load.

- Dispensers:Keep your warehouse floor clear of awkward pallet stacks and avoid the risk of knocking a pile of pallets over. These dispensers keep pallets contained and make it easy to retrieve one at a time.

- Tippers and Upenders:Pallets, rolls and oils often need to be tipped onto their side for easy manipulation. Accomplish that safely with a tipper or an upender to increase warehouse efficiency and worker safety.

- Pallet Inverters:Instead of stacking and unstacking product by hand, use a pallet inverter to transfer loads from one pallet to another.

- Spacers and Pallet Retrievers:These are usually needed by meat processing plants and cold storage facilities, tipping the pallets on their side so you can retrieve or place any necessary spacers.

Having one or more of these tools can help with efficient warehouse organization while reducing unnecessary manual labor and potential work related injuries.

Work Stations

Injuries from heavy lifting are one of the leading causes of workers' compensation claims in the United States. More than36 percent of these injuriesresult in missing work days. While proper lifting techniques can help reduce the number of workplace injuries,workstations with lifting tableseliminate the need for such manipulations.

These workstations should be located anywhere pallets are loaded, as well as places that have bins, boxes or other containers a worker may need to sort through. Getting these containers up off the floor or onto low shelves can reduce back strain injuries.

Pallet Washers

To enhance both safety and cleanliness in your facility it is especially useful tohave a pallet washing station. These stations help minimize the risk of cross-contamination and can be used to wash plastic and aluminum pallets. It can also be used to clean freezer spacers, containers and totes to reduce the risk of spreading dust, allergens or even dangerous bacteria like E. coli, listeria, and salmonella.

Stretch Wrappers

Wrapping a fully loaded pallet in shrink wrap is a tedious and time-consuming process if you do it by hand. Save time and increase your warehouse's efficiencywith a stretch wrapper. All your workers need to do is load a full pallet into the stretch wrapper, and the device does the rest, securing the load to the pallet so it can be safely moved. This equipment can save your crew substantial time and stretch film by automating one of the most tedious but necessary duties.

Storage Area

This section of the warehouse plays an essential role in the overall management of inventory. For example, Pallet Dispensers can help keep yourpallets off the main floor, but you ultimately will need somewhere to store the remaining pallets when not in use. The best way to economize your storage area is with multi-tiered pallet racking that include wire decks for that extra measure of pallet support. This is a great place to keep unused pallets that will not need to be used for an extended period of time.

These are just a few of the tools available to create a layout for warehouse efficiency that protects both your product and your team.

Contact us todayto learn more!